Transforming Marketing Collateral Production: A Dynamic Publishing Success Story with SHIFT in the Tire Manufacturing Industry

Introduction

In the highly competitive world of manufacturing, where products are sold through a vast dealer channel, the need for accurate, brand-compliant, and timely product collateral is crucial. A leading tire manufacturer faced numerous challenges in this aspect, involving multiple stakeholders, decentralized data, and a complex collateral creation process.

This case study explores how SHIFT, leveraging its dynamic publishing capabilities, played a pivotal role in helping them overcome these obstacles and bring accurate, brand-compliant product collateral to market faster and more cost-effectively.

Client Background

The tire manufacturer, a global industry leader, faced the complexity of managing an extensive product portfolio while ensuring brand consistency across large dealer and distribution channels. The traditional methods of creating and updating product collateral proved to be time-consuming and prone to errors. Seeking a solution to streamline these processes, the company turned to SHIFT.

Challenges

- Decentralized Data: Product data were stored in multiple locations, leading to errors in collateral due to inconsistencies.

- Brand Inconsistencies: With a diverse range of products, ensuring that all digital assets, including brand fonts, logos, and product images, were consistently used proved to be a significant challenge.

- Approval Bottlenecks: The approval process for product collateral was manual and time-consuming, causing delays in bringing materials to market.

- Individual Design Processes: Each piece of collateral was individually created by designers using software like InDesign and Illustrator, resulting in a lack of standardization and inefficiency.

The SHIFT Solution

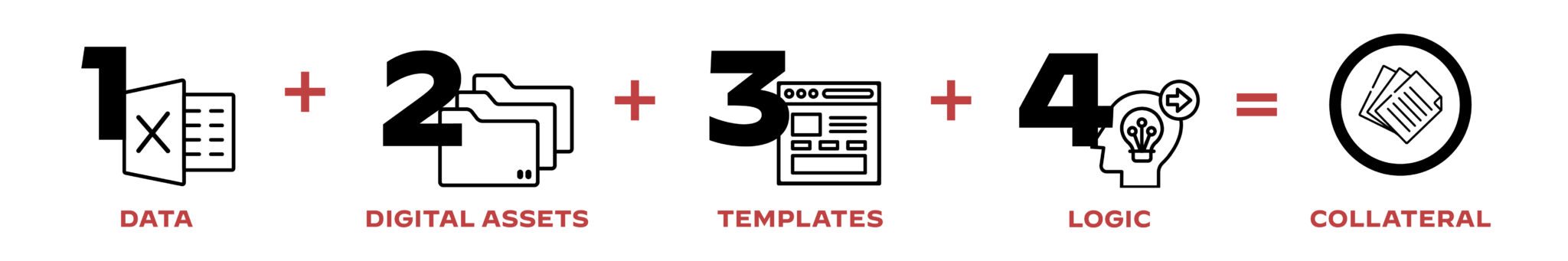

SHIFT implemented a dynamic publishing solution, addressing the client’s challenges through the following key features:

- Standardized Database: SHIFT created a centralized database containing all product data, ensuring that information was accurate, up-to-date, and consistent across the organization.

- Digital Asset Centralization: All brand fonts, logos, and product images were centralized and standardized within SHIFT, eliminating the risk of using outdated or inconsistent digital assets in marketing collateral.

- Pre-Approved Templates: SHIFT worked with the client to create templates for product collateral that were pre-approved, ensuring that the marketing team adhered to brand guidelines while having the flexibility to customize within set parameters.

- Documented Logic: SHIFT documented the logic required to feed product data and digital assets into the pre-approved templates. This streamlined the process of creating collateral, reducing the likelihood of errors and ensuring brand compliance.

- Dynamic Collateral Generation: Using the standardized database and templates, the solution dynamically generated collateral efficiently and accurately. Any changes to product data or digital assets were automatically reflected in the collateral, reducing manual effort and the risk of outdated information

Results

The implementation of SHIFT’s Dynamic Publishing Solution yielded significant benefits for the tire manufacturer:

- Cost Savings: By automating the creation and distribution of collateral, the company experienced over 2000% cost savings per year over conventional desktop work.

- Speed to Market: The streamlined processes and template-based design significantly reduced the time required to create and update collateral. New product launches and updates could be communicated to the market faster than ever before.

- Brand Consistency: With pre-approved templates and centralized digital assets, SHIFT helped the client maintain a consistent brand image across all marketing collateral, reinforcing the brand’s identity in the market.

Savings over 2000% per year over conventional desktop work

Conclusion

SHIFT’s dynamic publishing capabilities proved to be a transformative solution for the tire manufacturer, empowering its marketing and brand teams to bring accurate, brand-compliant collateral to market faster and at a lower cost.

Because of these successes, dynamic publishing has been brought into other business units within the company. In addition, its ability to centralize, standardize and templatize helps mitigate the impact of employee turnover, ensuring continuity in collateral creation. In the competitive landscape of tire manufacturing, SHIFT positioned the client as a leader in agile and cost-effective marketing practices.